How Do Compression Fittings Work, and What Are They? Everything You Need to Know

Compression fittings are essential components in industrial piping systems, providing a reliable, easy-to-install, leak-proof connection between tubing.

These fittings are widely used across various industries, including oil and gas, pharmaceuticals, water treatment and chemical processing, due to their ease of installation and versatility.

If you’ve heard about compression fittings, but have never found a reliable source that answers all your relevant questions, you’re in luck.

This guide provides a comprehensive understanding, answering all your compression fitting questions and more, from how they work and what their major advantages and best practices are, to what makes Ibex Australia’s VIS-LOK compression fittings the perfect choice for your needs.

How do compression fittings work?

Compression fittings create a reliable, leak-proof connection by mechanically compressing components around the pipe or tubing. There are three main components involved in compression fittings:

- Nut: This is the threaded component that you use to screw onto the body of the fitting.

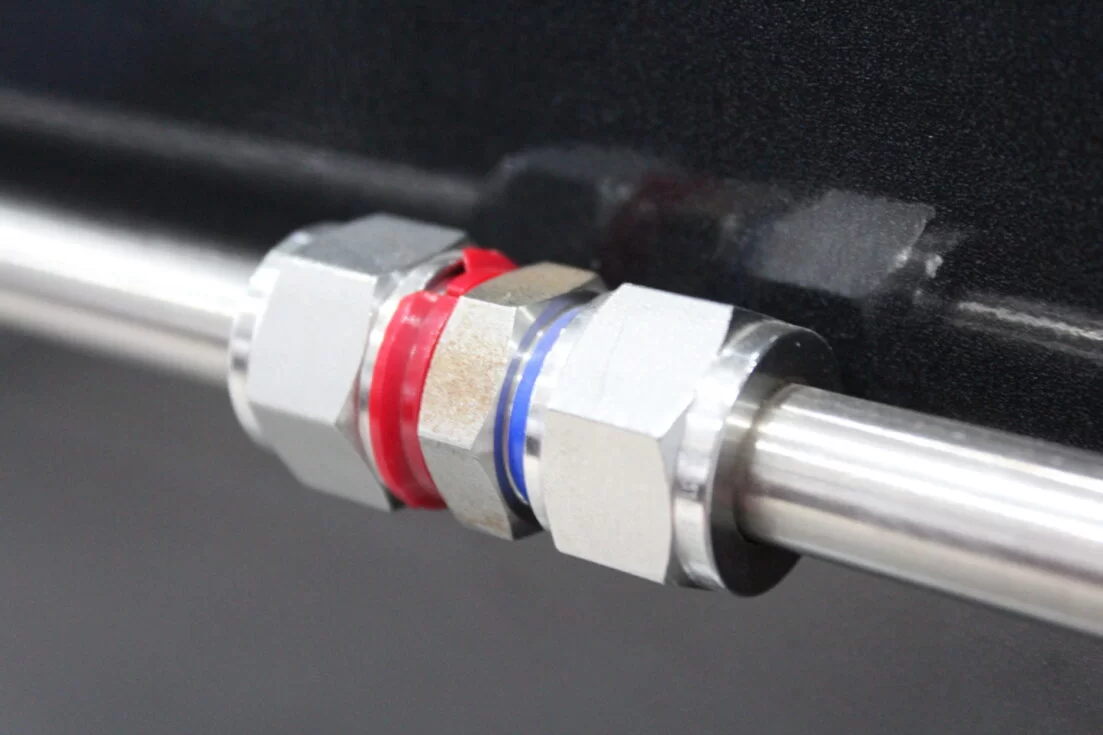

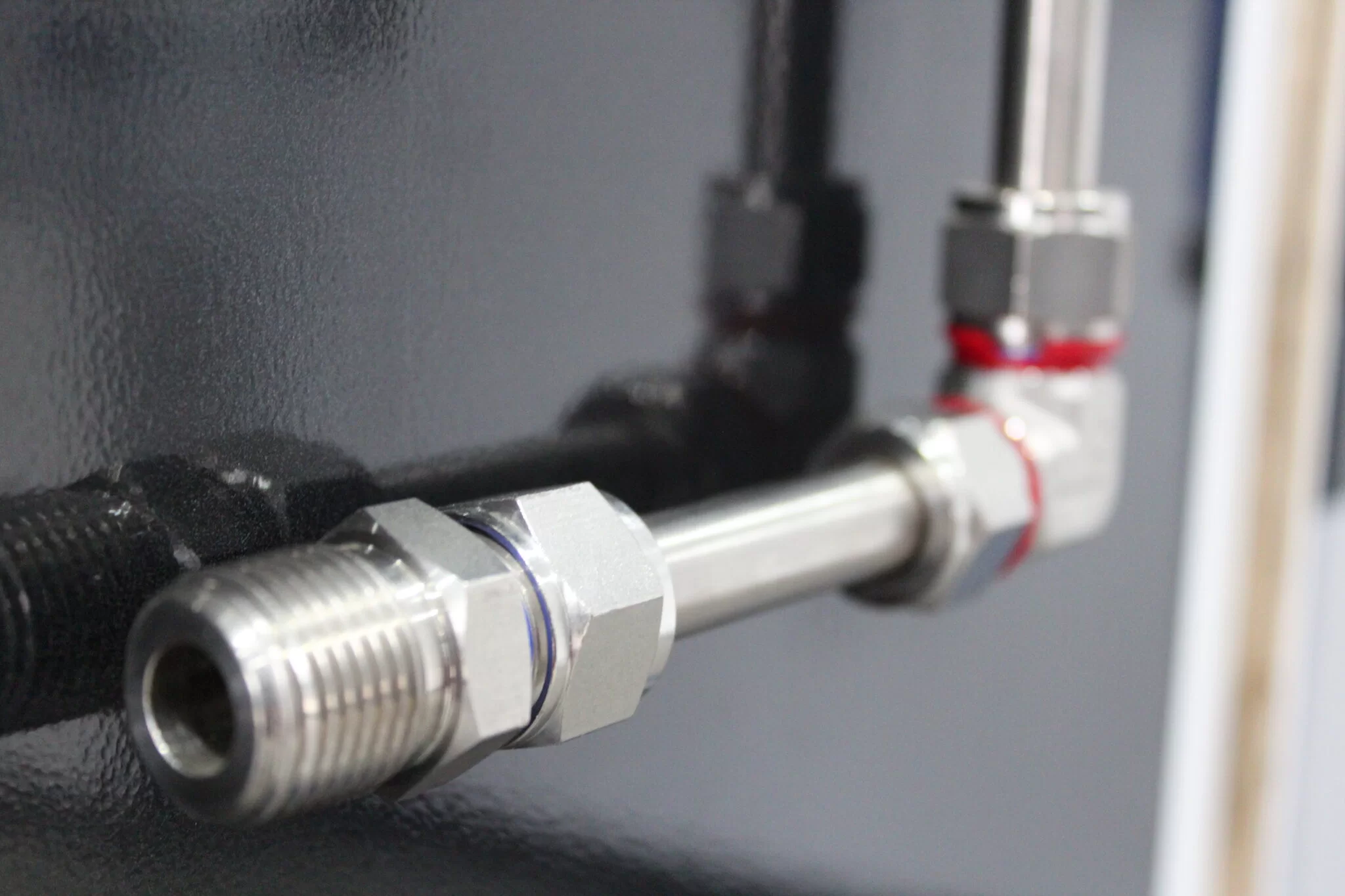

- Ferrules: These are ring-shaped pieces that fit around the pipe. They’re typically made of metals, such as copper, brass or stainless steel, or plastic. Single ferrule fittings usually require one ferrule, whereas twin ferrule fittings (which are the type of ferrule fittings we stock at Ibex) require two.

- Body: This is the main component of the fitting that houses the pipe and ferrule(s). It has threads to receive the nut and a connection for the pipe or tubing.

Now that you have an understanding of the pieces involved in compression fittings, here’s a detailed explanation of how they work together at each stage of the installation process:

- Preparation: The first step of compression fitting involves cleaning the end of the pipe or tube and ensuring the pipe end is smooth. This helps make sure no debris or burrs impact the flow of liquid or gas through the pipe, and that the ends are smooth enough to create a proper seal.

- Assembly: Once clean and smooth, you can start assembling by sliding the nut onto the pipe or tubing, followed by the ferrule(s). The ferrule(s) are crucial here, as they provide compression and create a seal when the nut is tightened.

- Tightening: Next, you’ll screw the nut onto the fitting body using a wrench to tighten. As the nut is tightened, it compresses the ferrule(s) against the pipe and the fitting body, creating a secure, leak-proof seal. If you’re using an Ibex Australia VIS-LOK Compression Fitting, you can rely on our red check ring to tell you when your fitting has reached the correct tightness. Once your fitting has reached the correct tightness, the check ring will pop off the fitting, eliminating any over- or under-tightening risks.

For product enquiries, please email us here.

Article by: Ibex Australia

Supported by:

About Statewide Mining Supplies

Statewide Mining Supplies vision is to become a cornerstone in the Australian mining industry for decades to come. Our mission is to provide high-quality, safe and environmentally conscious chemicals, parts and services that enhance the efficiency and safety of mining operations. We are committed to sustainability, innovation, and the continuous improvement of our products and services. Our values are rooted in integrity, customer satisfaction, and a deep understanding of the unique challenges faced by the mining sector.